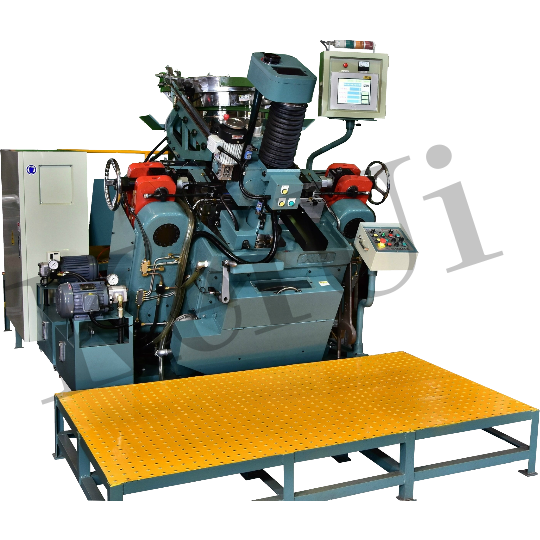

| Model | KU-240 |

| Suitable for screws | making low-carbon / stainless steel screws under gauged 3/8” (M10) |

| Main Motor | 10 HP (7.5kW), 6 pole, three-phase induction motor (Siemens) |

| Inverter | 11kW, Sanken (or Fuji), made in Japan |

| Bowl Vibrator | 1000mm, bowl style (standard equipment) (optional: 1200 vibrator) |

| Capability | #12(thread dia. 5.5mm) ~ 3/8” (thread dia. 9.5mm) screws, point No.1~No.6, screw length:30mm~250mm (Choosing 1200 vibrator: screw length up to 300mm) |

| Working Speed | Single Stroke 60~350 pcs/min; Double stroke 30~100pcs/min (depends on screw size, length, & feeding adjustment) |

| Lubricant Pump | 1HP (0.75kW), 6P x 2; with two separated oil tanks |

| Vibrator Lifting Motor | 2HP(1.5kW), 4P |

| Action Controller | Mitsubishi PLC (Program Logical Controller) With HMI (Human-Machine Interface) for easier operation |

| Brake Device | Air-Clutch Brake (rear) + Air-Disc Brake (front) |

| Machine N.W. | 7,920 KGS (the front, rear platforms aren’t included.) |

| Machine Dimension | 220(w) x 292(d) x 220(h) CM |

For the sake of improvement, we reserve the right to change the designs & specifications without notice.